Marshall's Jewelers has a 64 year history of designing fine pieces of jewelry for individuals. Whether you have family gems or diamonds you wish to restyle and have us create a unique piece of jewelry for you or a loved one, designers will work closely with you to create that one-of-a-kind masterpiece that you most desire.

Start a Custom Design

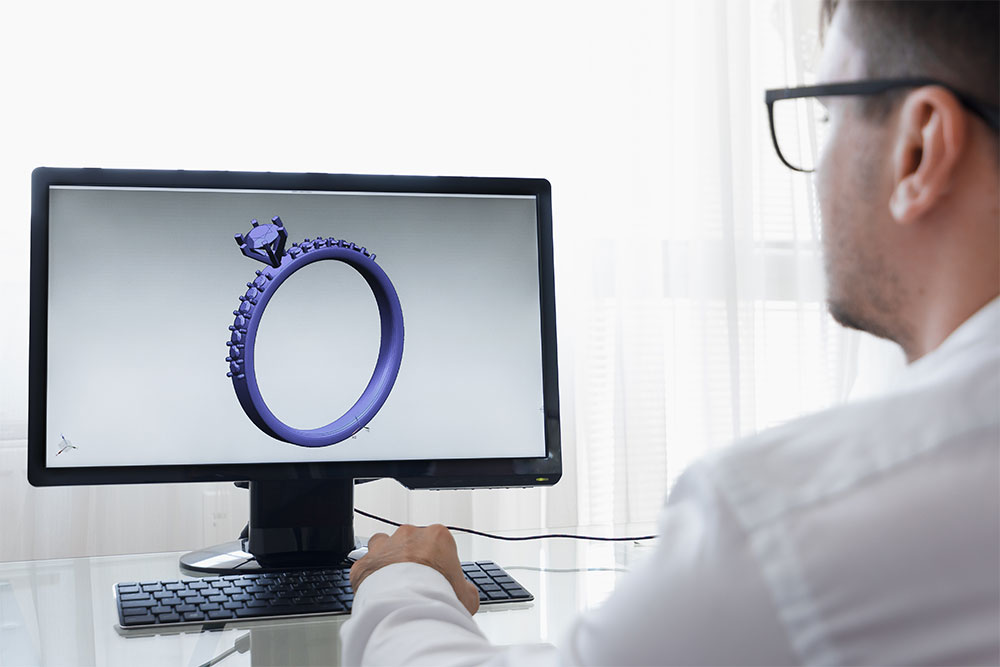

Computer Aided Designs

We have always used the most modern equipment and employed the newest techniques. The next step is Computer Aided Design (CAD). No longer are 2 dimensional black and white sketches the norm. CAD has defined the new standard by giving you fully rendered 3 dimensional color view of any concept that we are creating for you. Here are a few examples of how powerful this really is.

Custom Design Process

We work with you to customize every detail of your special customized jewelry piece. The typical process includes:

-

Sitting with you to determine your overall idea of what you want

-

Choosing the type of item (we can create just about any type of custom jewelry. Rings and pendants are the most common, but we have done a wide variety of items including money clips, cuff links, and custom brooches.)

-

Choose the material (We can use any type of metal including 14K and 18K gold, silver, and platinum).

-

Sketch the item – this ensures that we have the right idea of what you want

-

3D Rendering via Computer Aided-Design (CAD) – We use the most advanced CAD system on the market and we can show you, in 3D, exactly what your custom jewelry will look like.

Production

-

Wax mold – We create a wax mold of the item from the 3D rendering

-

"Invest" the mold – basically creating mold with a plaster-of-paris type material

-

"Debubblize" the mold – we put the mold in a vacuum to extract any bubbles

-

"Burn-out" the mold – heat the mold at high temperatures for a long period of time to remove any wax and wax residue

-

Cast the item – we melt gold in a crucible and pour it in the mold

-

Break away the mold – once solidified we break away the mold revealing a ‘rough casting’

-

Clean, polish, and insert stones